HOLDING STRENGTH

RAPTOR® composite staples have stronger tensile holding power compared to similar sized metal staples.

MECHANICAL PROPERTIES

| TENSILE PEAK FORCE DATA | |

| RAPTOR® | 24 lbs. |

| METAL | 16 lbs. |

| SHEAR PEAK FORCE DATA | |

| RAPTOR® | 25 lbs. |

| METAL | 47 lbs. |

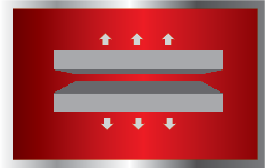

TENSILE DIRECTION

SHEAR DIRECTION

CHEMICAL RESISTANCE

RAPTOR® polymer composite staples have strong resistance to chemicals and maintain their strength even after long-term immersion in most liquids including organic solvents, aqueous solutions and automotive fluids such as these listed to the right:

CHEMICAL RESISTANCE

| ORGANIC SOLVENTS | AQUEOUS SOLUTIONS | AUTOMOTIVE FLUIDS |

| Alcohol | Acid | Gasoline |

| Acetone | Base | Oil |

| Trichoroethylene | Saline | Grease |

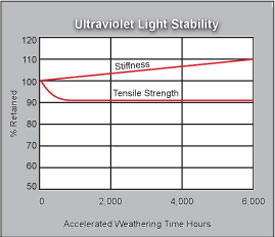

ULTRAVIOLET LIGHT STABILITY

RAPTOR® composite staples maintain their strength even after 6,000 hours of accelerated aging by exposure to UV and moisture.

THERMAL PROPERTIES

- Drivability performance unaffected by low temperatures (Tested down to-30°F).

- Continuous Use Temperature: 350°F

- Short Duration Temperature Limit: 500°F

- Ash Temperature: 900°F

DIFFERENT GRADES

-

STANDARD MATERIAL:

Provides best drivability; will damage high speed steel moulder knives.

-

LF MATERIAL:

Safe for most moulder blades; drivability is somewhat compromised.

-

NF MATERIAL:

Safe for all delicate blades; drivability is somewhat compromised.

PULPABILITY

RAPTOR® composite staples have been tested in the Kraft® process and do not dissolve or melt. The composite material is 100% recoverable and the density is 1.6 g/cm3 .