RAPTOR® composite nails have twice the tensile holding power compared to similar sized steel fasteners. The shaft of the nails fuse permanently with the material creating a powerful interfacial bond between the fastener and the material. RAPTOR® nails are UV resistant, chemical resistant and have high heat resistance. They do not become more brittle at cold temperatures.

REQUEST INFORMATIONFORM

HOLDING STRENGTH

Our tests show that, in pine, RAPTOR® nails cannot be pulled out if there is only 3/8” penetration into the bottom layer (fastener must be broken to separate). If penetration depth is greater, no additional holding power is gained (force to break fastener is the same). Further, the successful drivability of the nail decreases as nail length increases. For maximum holding power, it is important to use the shortest RAPTOR® nail that cannot be pulled out.

MECHANICAL PROPERTIES

TENSILE DIRECTION

SHEAR DIRECTION

MECHANICAL PROPERTIES

| TENSILE WITHDRAWAL DATA | ||

| METAL | RAPTOR® | |

| COIL-5 | 1851 | 206 lbs. |

| 1592 | 206 lbs. | |

| 1093 | 206 lbs. | |

| 16Ga | 37 lbs. | 97 lbs. |

| 15Ga | 42 lbs. | 113 lbs. |

| 14Ga | 85 lbs. | 142 lbs. |

1 = Ring Shank, Cement Coated, 2 = Smooth Shank, Cement Coated, 3 = Smooth, Bright

| SHEAR DATA | ||

| METAL | RAPTOR® | |

| COIL-5 | 2061 | 110 lbs. |

| 2202 | 110 lbs. | |

| 1633 | 110 lbs. | |

| 16Ga | 68 lbs. | 38 lbs. |

| 15Ga | 115 lbs. | 43 lbs. |

| 14Ga | 85 lbs. | 53 lbs. |

1 = Ring Shank, Cement Coated, 2 = Smooth Shank, Cement Coated, 3 = Smooth, Bright

CHEMICAL RESISTANCE

RAPTOR® nails have strong resistance to chemicals and maintain their strength even after long-term immersion in most liquids including organic solvents, aqueous solutions and automotive fluids such as these listed to the right:

CHEMICAL RESISTANCE

| ORGANIC SOLVENTS | AQUEOUS SOLUTIONS | AUTOMOTIVE FLUIDS |

| Alcohol | Acid | Gasoline |

| Acetone | Base | Oil |

| Trichoroethylene | Saline | Grease |

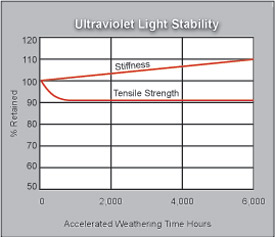

ULTRAVIOLET LIGHT STABILITY

RAPTOR® composite nails maintain their strength even after 6,000 hours of accelerated aging by exposure to UV and moisture.