LIGNOLOC® is the first collated nail system made of the renewable raw material beech wood that combines performance and sustainability perfectly. Ideal for all timber construction companies who want to implement their projects metal-free but also highly efficient.

With LIGNOLOC®, we have completely rethought fastening technology and brought back a sustainable, traditional fastener, developing it to meet today's requirements and sustainably change the future of construction. LIGNOLOC® is the world's first shootable wooden nail, ideal for industrial manufacturing and ecological woodworking. With the specially developed FASCO® pneumatic nailer of the LIGNOLOC® Edition, the nails can be easily shot into wood and wood-based materials and guarantee a strong, non-detachable connection. LIGNOLOC® is the most sustainable professional fastening system on the market, reducing CO₂ emissions by 66% compared to conventional systems and supporting the circular economy.

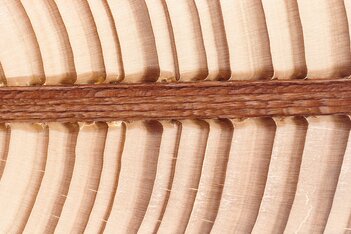

Did you know? LIGNOLOC® wooden nails impress with their high holding power. Thanks to Lignin Welding. Due to the special design of the LIGNOLOC® nail tip and the large amount of heat generated by friction when the nail is driven in, cause the lignin of the wooden nail to weld with the surrounding wood to form a substance-to-substance joint. Click the file below for a video demonstrating this great feature!

Demo-Lignin-Welding-Effect-2007-EN.mp4

01

Efficient and time-saving

LIGNOLOC® wooden nails are shot in pneumatically. Pre-drilling and gluing as with wooden dowels is therefore completely eliminated.

02

LIGNOLOC® also convinces with thermal advantages. The extremely low thermal conductivity (0.64W/mK) of the wooden nails prevents the formation of thermal and cold bridges.

03

Post-processing without tool wear

LIGNOLOC® wooden nails protect tools and saw blades during the finishing of wooden elements in prefabricated house construction.

04

Corrosion and chemical resistant

LIGNOLOC® wood nails can be used both outdoors and in corrosive environments, as they do not rust and are resistant to swelling and fungal attack.

05

Long term beautiful appearance

LIGNOLOC® wooden nails stand out for their natural look and feel. The nails do not react with the ingredients in the wood, which means that these properties remain even after years.

06

When using LIGNOLOC® wood nails, there is no abrupt failure in case of fire as with steel nails. The nails behave like massive wood in case of fire.

07

The LIGNOLOC® wooden nail technology is patented and thus offers our partners a high differentiation potential.

LIGNOLOC® WOODEN NAILS: NOW WITH EPD!

We have received the official EPD (Environmental Product Declaration) for our LIGNOLOC® wooden nails! Based on the official Life Cycle Assessment (LCA) of our collated wooden nail, the EPD shows all environmental aspects throughout the entire lifecycle of LIGNOLOC®.

SEE EPD-DOCUMENT (IN GERMAN LANGUAGE)

LIGNOLOC® - NOW WITH EU-WIDE APPROVAL

At fastening pioneer BECK, the European Technical Assessment was eagerly awaited. As early as 2020, the German Institute for Construction Engineering (DIBt) issued the German “National technical approval / general construction technique permit” for “Load-bearing timber connections using LIGNOLOC® wooden nails”. Now the nails made of wood are also available with EU-wide approval!

WHAT DOES THE APPROVAL MEAN FOR YOU?

The approval enables the planning, design and execution of load-bearing connections in timber frame construction. Planks and panels made of solid timber, wood-based materials or gypsum fiber can be attached to wood building materials using LIGNOLOC® wooden nails. In addition, connections can be made with LIGNOLOC® to produce bracing and load-bearing wall diaphragms. LIGNOLOC® opens up entirely new possibilities in ecological timber construction. More sustainable. Nail by nail.

With LIGNOLOC® it is possible to connect wood to wood with wood. And thus create the most natural and ecological connection of all.

LIGNOLOC® wooden nails stand out for their ecological properties, starting with the use of European beech as a renewable raw material and short transport routes. According to a study by the Nova Institute, the production of a LIGNOLOC® wooden nail generates only 34% of the CO₂ greenhouse gas emissions compared to a technically equivalent steel nail. This means that CO₂ emissions can be reduced by up to 66% compared to conventional systems.

The wood of the European beech is ideal for the production of LIGNOLOC® wood nails. Its straight growth guarantees a homogeneous cell structure. During the production process, the wood is modified by compression, resulting in an extremely dense nail. This nail is highly resistant to internal and external damage, including fungal attack. Since wood is sustainably available and binds CO₂ like the trees in the forest, wood products like LIGNOLOC® are the perfect choice for climate-friendly construction of the future.

The LIGNOLOC® system opens up many possibilities for you. The nails are available in various diameters and lengths. Since January 2023 brand new also with head perfect for outdoor applications. For the portfolio of nails, there are two handheld tools and two nailing heads for robots or portal CNC machines for stationary applications. Thus, it adapts exactly to your requirements.

01

The innovative wooden nails are available in different diameters and lengths. Contact us to discover the right product for your project now.

02

LIGNOLOC®wooden nails with head

New in the product family: the LIGNOLOC® wood nail with head. The ideal fastener for façade construction.

03

The two specially developed LIGNOLOC® F44 and F60 pneumatic nailers provide the necessary power to shoot the wood nails directly into wood or wood materials.

04

In addition to the two handheld tools, BECK also offers two LIGNOLOC® nailing heads. Optimal for mounting on multifunctional bridges and individually adaptable to commercially available industrial solutions.

05

With LIGNOLOC® you have the choice. Whether the F44 system for processing wooden nails with a diameter of 3.7 mm, the F60 system for processing LIGNOLOC® nails up to 90 mm in length and LIGNOLOC® with head or the LIGNOLOC® nailing heads, we offer several systems to suit your requirements.

The LIGNOLOC® system from BECK opens up countless application options for you – whether it be indoors, outdoors or in areas susceptible to corrosion.

LIGNOLOC® wooden nails can be used in various ways in the production of multilayer solid wooden boards. Depending on the manufacturing process, they are used for fixing the layers temporarily or as a replacement for aluminum nails and wooden dowels, or else they give a rise to entirely new processing methods. This means time-related advantages and ecological benefits for the industry.

LIGNOLOC® CROSS LAMINATED TIMBER PANELS (LCLT)

The following wall panels can be made:

- LOAD-BEARING WALL PANELS

- NON-LOAD-BEARING-WALL PANELS (partition walls)

- METAL AND GLUE FREE WALL ELEMENTS thanks to LIGNOLOC®.

- The benefit of this wall design (in addition to the lack of glue) is the more elastic behavior compared to a glued CLT wall. This enables a better distribution of the load in the floor connectors, in contrast to the rather punctual load transmission of a (glued) CLT wall.

NAIL LAMINATED TIMBER (NLT) PANELS WITH LIGNOLOC®

- LOAD-BEARING WALL PANELS: No approval necessary, as the load is transferred via the timber boards used.

- CEILING PANELS: No approval necessary, as the load is transferred via the timber boards used.

With LIGNOLOC® we have developed a new, groundbreaking product whose idea and unique properties are inspiring. LIGNOLOC® has already won many awards, such as the German Design Award for innovative product design. We celebrate every award, but we are even more enthusiastic about the implemented projects and the success of our customers with LIGNOLOC® - because that's what it's all about.